Our company profiles are already available on this website, if you want a complete profile of our company with the .pdf format, you can contact us through our email in central@megatek.co.id or can contact us via our stated at page bottom on every page of the website we..

Megatek Konsindo was established on July 29th 1998 it has ISO 9001:2015, ISO 45001:2018 and SNI ISO 14001:2015 certifications . Our management has more than 40 years of experiences in handling NDT Services Projects. Megatek Konsindo is a pioneer in developing advance NDT inspection in Indonesia. We have a variety of X-Ray Crawler Machines for both onshore and offshore pipeline to reduce cycle time and shorten projects schedule.

Megatek Konsindo several business stream namely:

Delivering Quality Services Anywhere, Everywhere..,

To be recognized as one of the greatest company in providing NDT Services.

We will always be there for our clients and provide effective solutions with our capabilities. We aim to forge an excellent working relationship through clear client communication channels. We will ensure all technical and quality assurance services meet the client’s requirements.

We are fully aware that technical and quality assurance services which will be given to all project assigned must meet requirements of client needs, demand and objectivity, therefore we are taking action, reaction and consideration to what our customer ask for in order to make projects assigned done properly.

Megatek Konsindo has experience working in remote and rural areas with limited resources. Despite these challenges, we are capable of mobilizing our people and equipment to ensure the completion of our projects.

Most of our equipment are tailored to the project requirements and are built to withstand any terrain in any country.

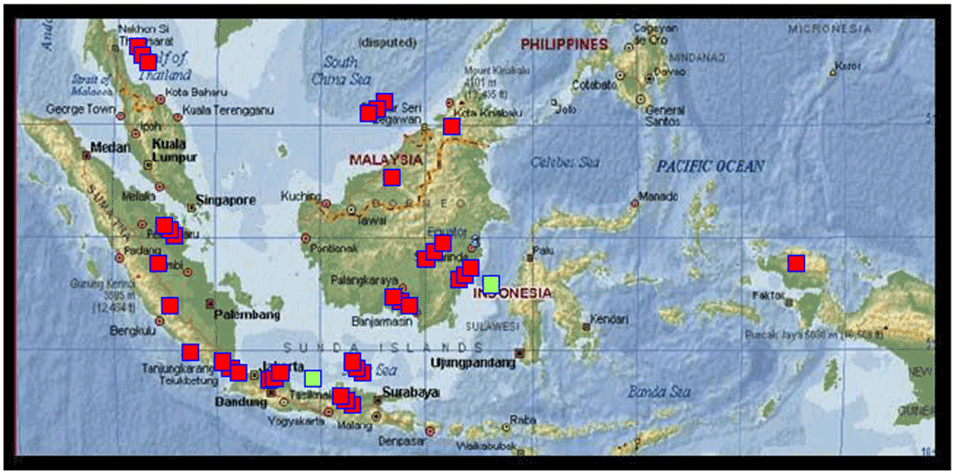

Megatek Konsindo had executed and completed various projects both Onshore and Offshore in Indonesia and overseas. Our Sister Companies to explore through partnership with associated in Singapore, Malaysia and India. Our project track records and ongoing projects are mentioned below.

Detail project shall refer to our Company Experiences track record :

Megatek Konsindo employ and train both engineers and technicians from various institutions to utilize the advance method in Non Destructive Testing and Inspection to meet International Standard of qualification to ASNT LEVEL 1, 2,3, PCN LEVEL 2 and also BATAN, B4T, etc.

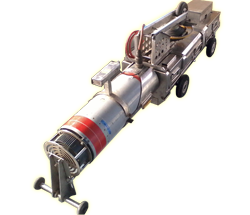

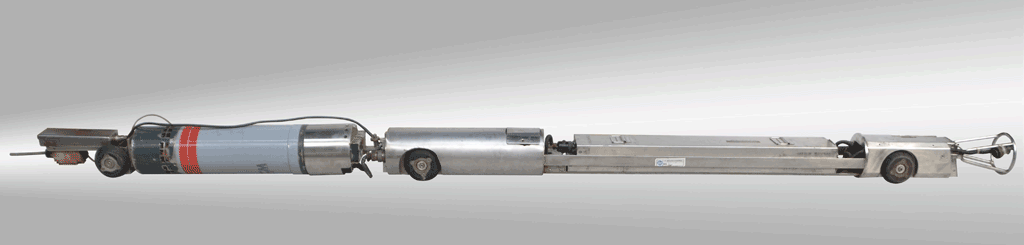

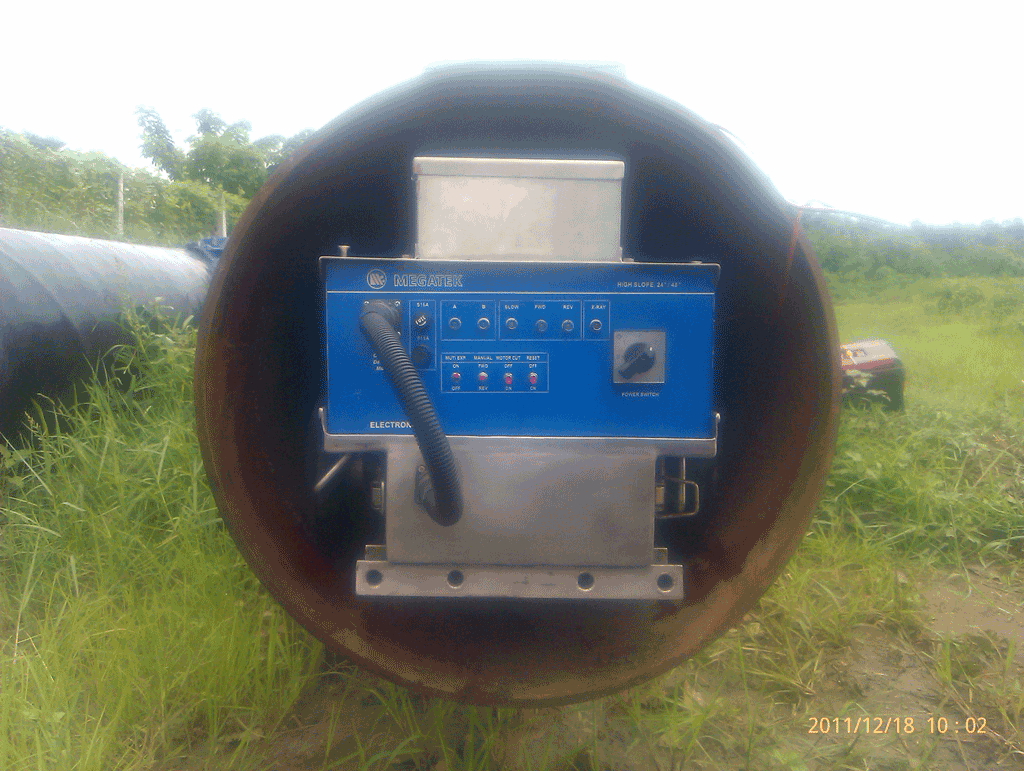

Megatek Konsindo are fully committed to the Pipeline Industry in NDT method, our Research and Development Group of Engineers have develop highly rugged extremely liable X-Crawler facility utilizing the combination technology of developing highest safety and multiple exposure change technique utilizing into microprocessor specially build in three different kind motor drive system called: belt driven, shaft driven and normal drive system to meet both onshore and offshore pipeline terrain X-Crawler facilities.

Megatek Konsindo has a wealth of experiences after going through various of projects terrain from normal to hilly mountain in obtaining up to 280 to 400 degrees climbing X-Crawler facilities system.

Megatek Konsindo has adopted to support pipeline contractors both onshore and offshore on inspection of normal and special coating pipes utilizing Holiday Detection to detect porous area of the coating.

Our Crawlers are capable of inner diameter from 5" up to 48" tailored to meet various pipeline diameters both for onshore or offshore each having a different capabilities as belt driven,shaft driven and normal driven, to smoothen the project operation.

X-Directional machine are capable of any method for external piping / pipeline diameter and very suitable for Raiser Radiography utilizing Megatek Konsindo special tailored design X-Ray Tube Universal fitting, operated by ease two-men team.

Holiday Detection use to locate discontinuities as pinholes / holes or void in the coating film, which exposes the substrate to corrosion. Typically, Holiday Inspection is performed by high volts of pulsed DC current depending on thickness of film coating. The codes reference specifications from ASTM and NACE Standard

Extracted from

Our reliable Technicians have a powerful ability to handle any job in each project, their qualifications and experiences gathered from projects would match any difficulties in overcoming project execution.

Megatek Konsindo has come a long way in getting the right X-Ray Crawlers to support our Technician in the pipeline industry, especially in the onshore pipeline with various terrain hilly to mountain seriously encounter in extremely marshes terrain. In comparing with offshore barge S lays pipeline system.

Both our engineers and technicians are mentally qualified in handling any sophisticated projects to meet the right cycle time requirement in project execution.

Mr Chand says “The terrain is extremely harsh, and is made up of rocky, mountainous slopes with an altitude of up to 3,300 feet, dense forests, swamps and palm oil plantations. Steep, 76° slopes have been encountered, and the undulating terrain has resulted in 39 per cent of the pipeline consisting of field cold bends – a total of 16,380 bends.

“Thinking out of the box to find a solution to the inhospitable terrain, our project team modified trailers and sledges to suit the mountainous terrain. All the vehicles were provided with full-width off-road tyres and excavators with special track grip for steep slope locations. Our project team has also used specially designed internal crawlers for non-destructive testing of the pipeline.”

“At this project Megatek Konsindo was involve as a NDT subcontractor”

Our both Shaft Driven 2448 - 40 deg X-Crawler and Belt Driven 2448 - 28 deg X-Crawlers was ultimately utilize in Sabah Sarawak Gas Pipeline in the extremely hilly to mountain terrain as show photos.

Our Technicians are fully trained in handling various kinds of X-Ray Machines with special fitting design both for pipeline and piping system.Proper testing and checking background are conducted to each Technician before they mobilized to sites.

Each Radiography team consists with technician qualified to PCN, BATAN, ASNT Level 2, our manning level are as follows:

Above team and its qualifications would be adjusted to the site needs and shall be approved by both parties.

Our mission having plant process piping multiple bends INTERNAL X-RAY CRAWLER was a problem solver economical tool high speed radiography going through 90 degrees pipe bend utilizing out MBX-CRAWLER-90-35-1648 Shaft Driven System compare to the slow process of external three to four exposure butt weld pipe joint technique cause delay in production.

Megatek Konsindo in-house engineer the MBX-CRAWLER-90-35-1648 SHAFT DRIVEN SYSTEM single wall single image RT method utilize both BLR Roll Pac Class II film or Digital IP Plate x-radiographic multiple exposures technique to overcome the heavy wall thickness, comply with pipelines and plant process piping codes and specification of API 1104, ASME B31.3, etc.

MBX-CRAWLER-90-35-1648 SHAFT DRIVEN SYSTEM utilizing internal (SWSI) both 180kv or 300kv x-ray tubehead depending on pipe diameter with capable technique of radiograph 70 to 120 pipe joints system based on self-propelled battery operated maintain high safety standard having external diameter range of 16 ins - 48 ins with climb angle of 35 degree shaft driven system.

Plant Process Piping - Pipelines with Factory Bends - Hot Bend System

Megatek history has been reach through International Network from mid 1999 to today operation of AUT. AUT of pipeline girth weld is characterized by the fact that the weld geometry is divided in portions characterized by their orientation and location in the weld. An automated scanning mechanism with a set of ultrasonic probe - one for each zone at both sides of the weld rapidly rotate around the pipe for volumetric weld inspection in one single scan. This approach achieves the short possible but also a reliable inspection. The capability of Focus Scan RX II to characterized and size flaws enables the application of engineering critical assessment based acceptance criteria for weld imperfections. The scanner running on the welding band uses two Phased Array probes for the inspection of two specific areas of the weld, the fusion line (bevel face / HAZ zone) an the volumetric area (deposited weld metal) TOFD is added to the probe configuration to make absolutely certain that no relevant-oddly oriented defects escape detection. It is common that the inspected are includes the heat-affected zone.

Our PAUT system equipped with both manual and motorize scanners for piping, plate and pipeline method of scanning procedure as low as small diameter range from 0.84 in, OD to 4.5 in diameter. Greater diameter can be utilize by the Plate scanners, Pipeline Radial Weld Scanners with all the system comes of with dynamic brake and lock system.

PA Multi-group inspection

Alternative to Radiography Replacement Phased Array Method has been the secondary Resources to X and Gamma Radiography techniques of recording similar defects such Incomplete Penetration, Incomplete Fusion, Crack, Slag Line/Inclusion and Porosity Family, etc. Largely use in piping, pipeline, LNG Tank, and boiler tubing inspection method with all major codes or (ECA) Engineering Critical Assessment compliance.

The above LNG Tank image courtesy of www.naturalgasasia.com extracted from:

http://www.naturalgasasia.com/tangguh-to-go-for-further-development

Megatek Konsindo Sub-Contractor of NDT Tanks Works LNG Tangguh. Main-Contractor Toyo Kanetsu Indonesia through JGC Japan

Our Services NDT Work :

NDT Support Facilities :

There has been other NDT method of performing testing inspection of 9% Ni steel LNG Tank as per API 620, easy an economical primary technique of 100% X-Ray radiographic testing utilizing both films or Digital into detecting defects of 20,000 linear butt weld seams. Our radiography interpreters together with field engineering make easily understanding of industrial applications in X-Radiographic method.

Megatek Konsindo in-house safety X-Ray focusing radiation collimated with the universal fitting combination of the X-Ray Directional utilize the highly safe manner for both NDE teams and welding engineering operational works can be carryout simultaneously, further utilizing the digital RT, 50% energy reduce small area of radiation.

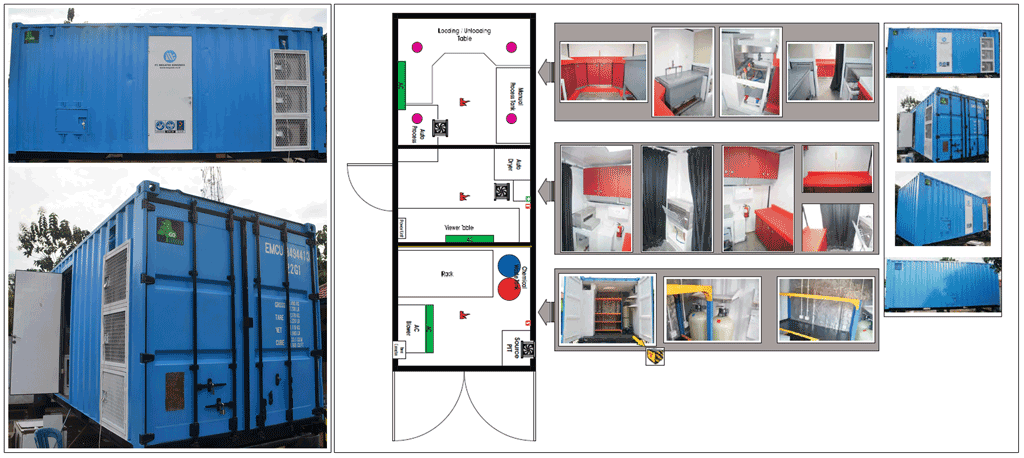

We, Megatek Konsindo has the capability of maintaining and repair X-Ray machines on site with other NDE resources include 3in1 darkroom facility fully equipped with films digitizing system for smooth running e- control project cycle times.

With reference to Automated Ultrasonic is allowed, if the rules under API 620 Appendix U are follow, based on many expensive factors of operation requirement methodology both in equipments and manpower management.

Conventional NDT Inspection is widely used in our industries on day to day production like Gamma Radiography, Magnetic Particle and Liquid Penetrant Testing, complying with various NDT Codes and Specifications.

Ultrasonic Testing is used for detection of flaw in the welded material utilizing various kinds of probes and technicians capabilities not limited to RP2X, AWS D1.1 codes and specification.

Magnetic Particle Testing is used in NDT field to inspect pipe bevel, weld and etc. to detect surface / subsurface discontinuity in Ferrous material.

Liquid Penetrant Testing is used for detecting surface defect based on capillary action.

Gamma Radiography provide detection in materials, Such as Welded Butt Weld or Casting for Defects and Discontinuities base on intensity of Radiation penetration, Utilizing Radiographic Film or Digital RT IP Plate / DR Plate Method.

Gamma radiographic techniques are utilize in various industry, such as Power Plants, Refinery, LNG Plant, Pipelines ON / Offshore and Production Station of Oil & Gas System with mechanical mechanism of Failsafe operation methodology.

Conventional Radiographic Techniques utilization of bigger area to carryout Radiation work to protect on the Unclassified Radiation workman around for safe operation from Radiation sources.

Gamma Failsafe Combination Method Technique for both Iridium 192 or Selenium 75 has the ability to accept sources sizes in it capacity with different activities energy. Highly Complex and Confine Radiation area in conjunction with the Flexible Radiographic Shield mats, Tungsten Guide Tube and Collimator combination can reduce radiation attenuation for Unclassified workman place to a safe level of 3 meter radius for 24/7 both teams productivity operation.

Especially design to support both onshore and offshore Radiography facilities to ease mobilization and increasing productivities as mentioned thoroughly in our company profile the requirement of project schedule and cycle time shortening.

Megatek Konsindo has developed to provide save environment operations in developing both 3 in 1 & 2 in 1 Darkroom facilities fitted with waste chemical storage tank, carbon filters and water filters for manual and auto processing systems.

The 3 in 1 Darkroom is divided into three divisions:

This 2 in 1 Darkrooom facility to support Tie-in, Push Pull, X-Crossing (Road & Rail Way Line) and Hook-Up Offhsore facility it come with 2 area operational:

Mobile Darkorom has capabilities of working and support pipeline facilities in rural and remote area as such as excess is limited in difficulties terrains.

Our operational facility is strategically located in south Jakarta geometrically center for economical mobility of personnel, equipment and ongoing 20ft / 10ft container go green darkroom facilities with a build-up area of 1300sqm in carrying out Administration, Operational, Logistic to support mobilisation / demobilisation and strong NDT X- Ray repair with R & D NDE equipments ( X–Crawlers / mollification X-Directionals and other as tailored to project requirement) on new development products to meet projects requirements.

We also have build-in workshop to perform both X-Radiographic Shielding Room and Welding facilities to carryout PQR, WPS & WQT with other engineering inspection techniques for one stop NDT in one roof.

Our company has been capable Repair and Services all type of X-Ray machine to support the industrial.

We Relife X-Ray Tubehead to new operational cycle time because it’s not easy to predict depend on life cycle with method usage factor.

Technically speaking X-Ray Tube life span is 2 years to 15 years depend on 24/7 cycle time both filament material and the heavy coil (HV) make the tubehead operational from 10,000 to 30,000 duty cycle hours (This system work like a light bulb).

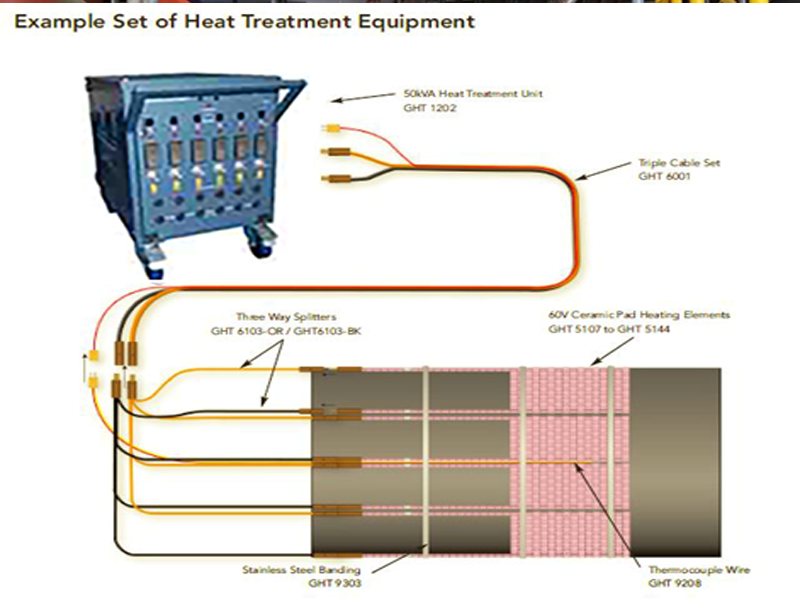

Megatek Konsindo also provide the following services both onshore / Offshore construction activities:

We Megatek Konsindo has been operating in the field of local Post Weld Heat Treatment, include Pre heat and Post heat method for site fabrication. Local heat treatment of pipes, tubes and pressure vessel is performed on weldment with adjacent material heated to subcritical temperature as per codes and standard. This PWHT method, process the welding residual stress to reduce the mechanical properties of both weldment and heat affected zone are improved. This possibility of brittle fracture of corrosion cracking can be reduce by pre-heat, post-heat and post weld heat treatment methodology.

PT. Megatek Konsindo uses Hardness testing with UCI Probe Suitable for low finished surfaces. Surface finish equivalent to 30 grind or better. The application of hardness testing enables you to evaluate a material's properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require.

Ferrite testing is a fast, inexpensive, and accurate way to measure delta ferrite content in austenitic and duplex stainless steels. Proper ferrite content provides a balance between ductility, toughness, corrosion resistance and crack prevention.Ferrite testing is a necessary process to avoid material failure in duplex stainless steel. If the ferrite content is too high or low, it is harmful for the material. If the ferrite content is high, the chance of corrosion increases.

Positive Material Identification (PMI) Positive material identification (PMI) is used to analyses and identify material grade and alloy composition for quality and safety control.

Positive material identification can prevent potential product failure in manufacturing.

Positive Material Identification (PMI) is the analysis of a metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. Typical methods for PMI include X-ray fluorescence (XRF) and optical emission spectrometry (OES)